By Katherine Wroth

•

December 16, 2025

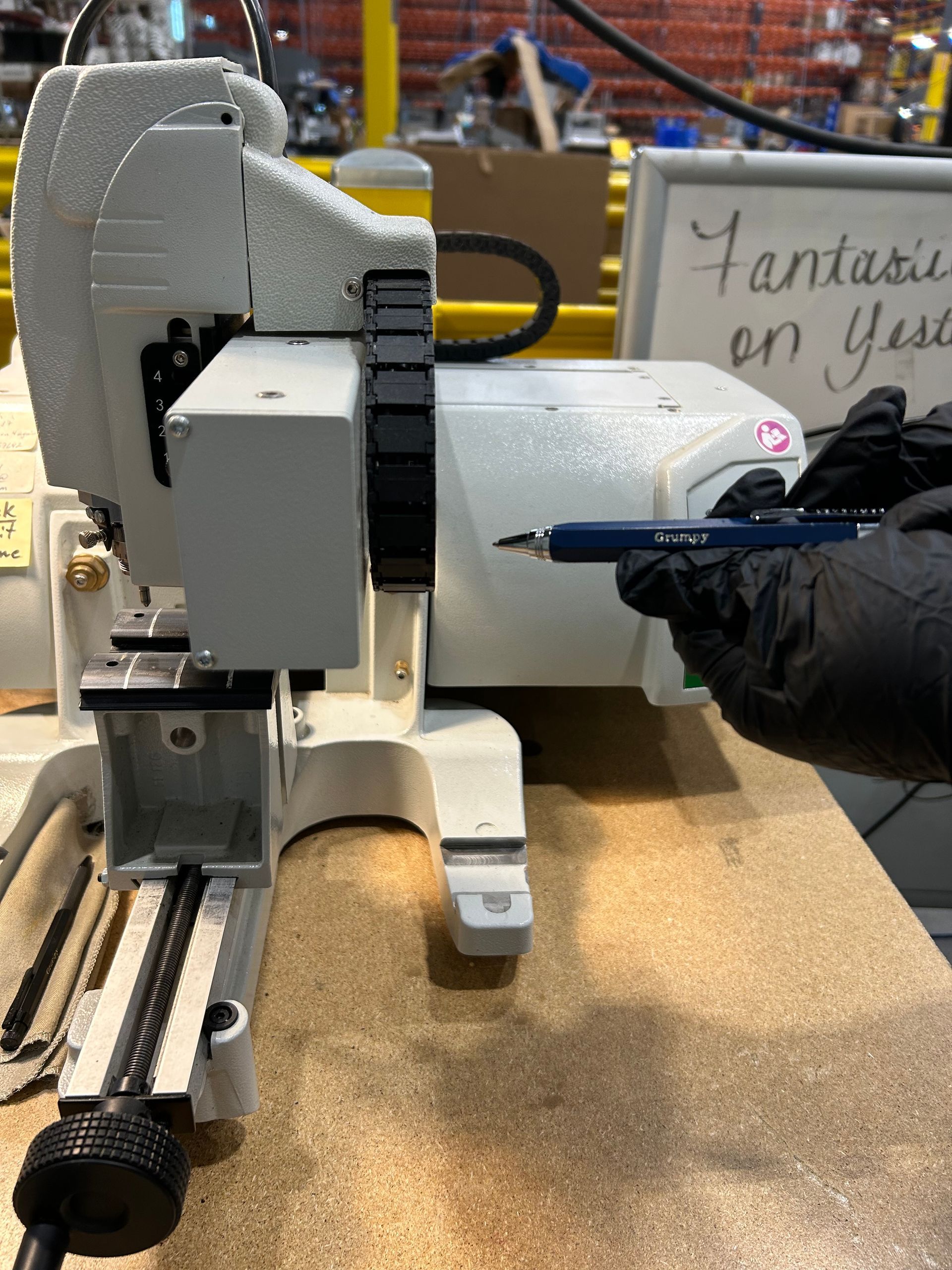

Warehouse automation isn’t new, but determining when it actually makes sense is where most companies struggle. Recorded live at WERC 2025 in New Orleans, this conversation brings together leaders directly involved in real-world warehouse automation decisions. Kevin Lawson interviews Chris Lingenfelter , founder of Robot Advisors, and our very own Tim Barrett , CEO of Barrett Distribution Centers. They sit down for a practical discussion on robotics, drones, and the hype surrounding automation. The focus stays on what actually matters: cost per unit, operational fit, employee experience, and ROI. If you’re evaluating warehouse automation or wondering why past investments haven’t delivered, this breakdown offers practical, experience-backed insights. Why Barrett took a robot-agnostic approach One of the most important takeaways from the WERC session: there is no one-size-fits-all robot. Barrett was an early adopter of autonomous mobile robots (AMRs), including systems from Locus Robotics and Six River Systems. But instead of standardizing on one solution, the company evaluates automation based on: SKU count and product size Order profiles and velocity Facility layout Customer growth expectations A footwear operation with serialized inventory has very different needs than an apparel fulfillment center, and Barrett treats them that way. The result: better outcomes for customers and lower long-term operational risk. Inventory drones: the unexpected game changer While AMRs get the spotlight, Barrett’s biggest automation win came from inventory drones. Using drone-based cycle counting, Barrett increased inventory count frequency by more than 7x while significantly reducing labor costs. For high-accuracy environments, especially serialized footwear inventory, this technology proved essential. The impact went beyond numbers: Higher inventory accuracy Faster exception resolution Better employee roles focused on analysis instead of manual counting In short, automation didn’t eliminate jobs. It made them better. How Barrett really thinks about ROI ROI isn’t ignored, but it isn’t the only metric. Barrett evaluates automation using cost per unit shipped rather than chasing flashy payback models. Capital investments are amortized based on contract life and redeployment potential, then layered with labor and operating costs. The guiding question is simple: Which solution produces the lowest sustainable cost per unit? That approach keeps decision-making grounded and aligned with customer outcomes, not tech hype. “To bot or not” starts with a baseline Chris Lingenfelter, founder of Robot Advisors, reinforced a critical point during the session: You can’t evaluate automation if you don’t understand how your warehouse operates today. Many companies struggle to answer basic questions: What does each unit really cost to ship? Where are labor inefficiencies hiding? Which processes are already working well? Before recommending automation, Robot Advisors helps operators establish a true baseline, then compare technologies objectively. Sometimes, the right answer isn’t robotics at all. That honesty matters. Automation as a competitive advantage for 3PLs For Barrett, automation isn’t just an operational tool. It’s a competitive differentiator. When engaging new prospects, the team often presents: Multiple automation paths Clear tradeoffs between solutions A data-backed rationale for each option That depth of analysis resonates with COOs and CFOs evaluating long-term fulfillment partners. It signals preparedness, transparency, and experience, not guesswork. The workforce question: what changes, what doesn’t As robotics adoption increases, warehouse roles are evolving. At Barrett, automation shifted labor away from repetitive tasks and toward: Exception management System oversight Data analysis Engineering and IT support Over time, this required growing centralized IT and engineering teams, a necessary investment to support advanced operations across multiple facilities. The takeaway from WERC 2025 was clear: automation changes work. It doesn’t eliminate the need for people. Thinking about automation, but not sure where to start? Contact us now for a free supply chain consultation.